CLEAN ROOM SYSTEM

EEPS uses panel are specifically high quality surface finishing for resisting chemical, alcohol and scratch. We offer various core and exterior panel skin materials of Polystrene, Polyurethane, Aluminum Honeycomb, Rockwool and etc. Quick and easy framing for ease and speed of installation. Systems include with glass window, door and auto sliding door solutions. No drilling operation for any joint, all fasteners are concealed for completed wall systems.

WALL and CEILING Panels are non-outgassing, non-particle shedding and anti-static. Tested in accordance with ASTM E595, these wall panels decrease product contamination. Its also can be applied to both Wall and Ceilings. We offer 44mm, 50mm, 75mm thk panels or custom made.

Products Specifications:

| Panel Cores available | Panel Skins available | Applications | Benefits | Technical Data | Variations |

|---|---|---|---|---|---|

| Aluminium HoneyComb | Prepainted Aluminium Sheet | Static Controlled Environments | Easy Cleaning | Tested in accordance with BS & MS Std | Opening at factory ancillary devices |

| Rockwool | Vinyl Lamination | Anti-Bacteria grade skin | No Exposed fasteners | Natural Anodized /Epoxy powder coated finished | Various core and skin configurations |

| Polystyrene (PS) | High Pressure Laminates (HPL) | Controlled Environment | Engineered design for Easy Installation | Standard Size -6mm, 13mm, 55mm | |

| Polyurethane (PU) | Stainless Steel | Food/Bio Industry | Epoxy adhesive Colorbond prepainted steel | ||

| Prepainted steel sheet | Aluminium HoneyComb | Aluminium Accessories |

Rockwool Panel

Polyurethane (PU) Panel

Polystyrene (PS) Panel

Aluminium Honeycomb Panel

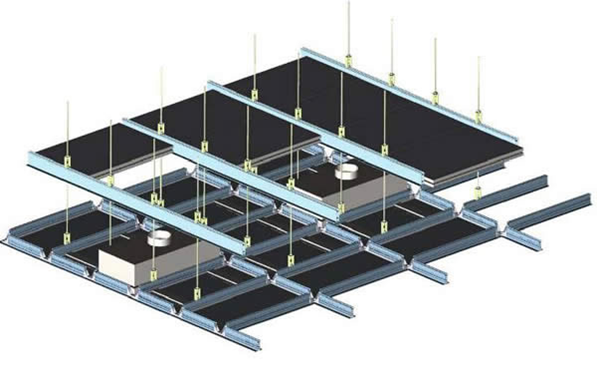

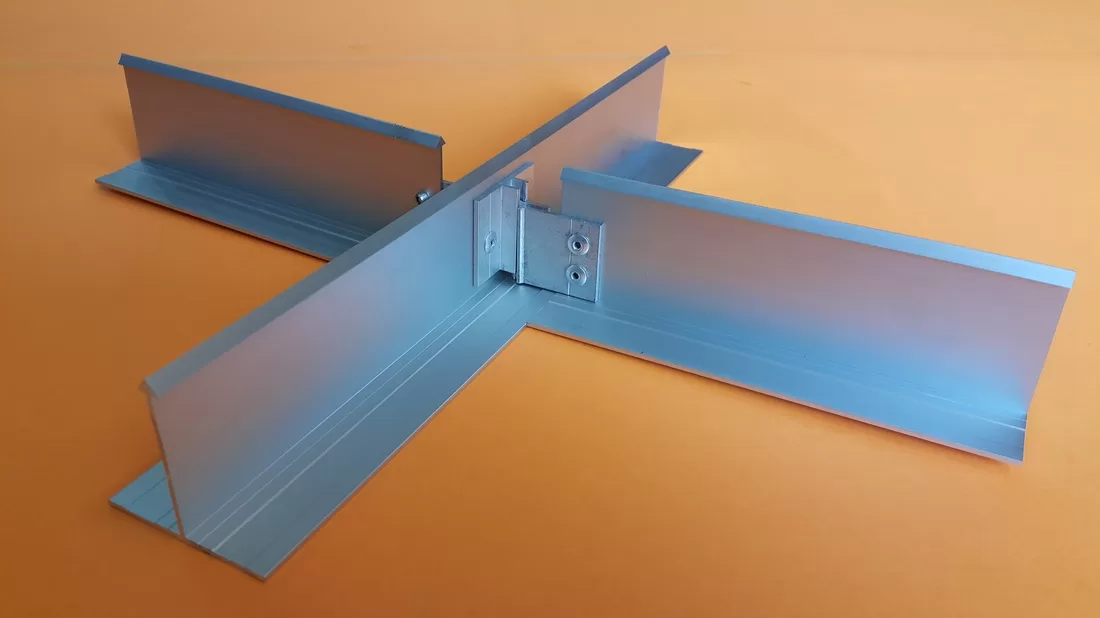

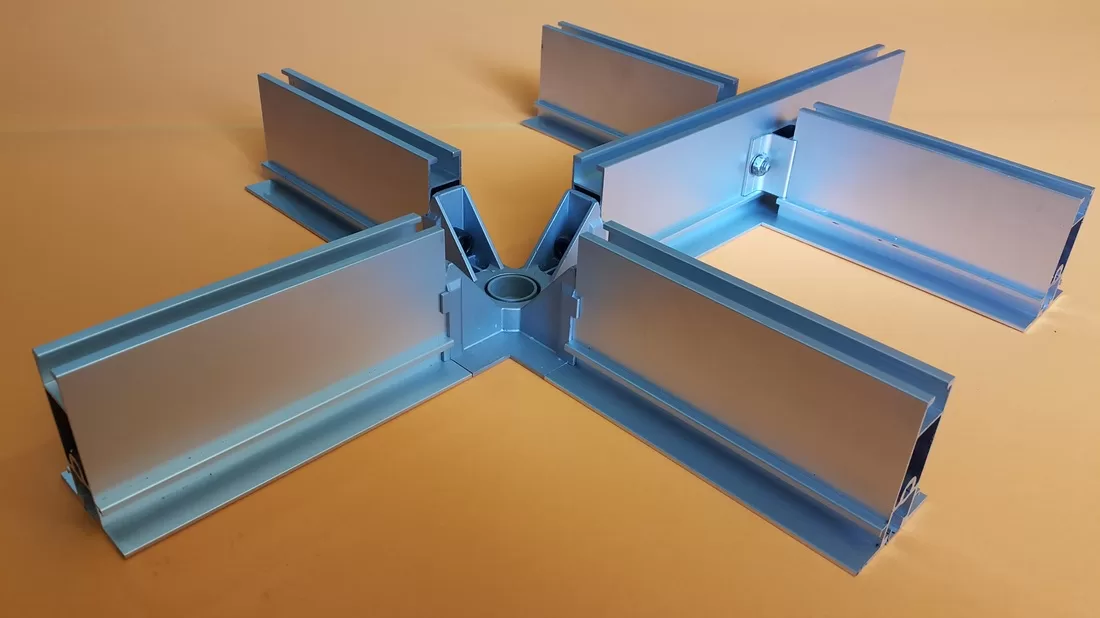

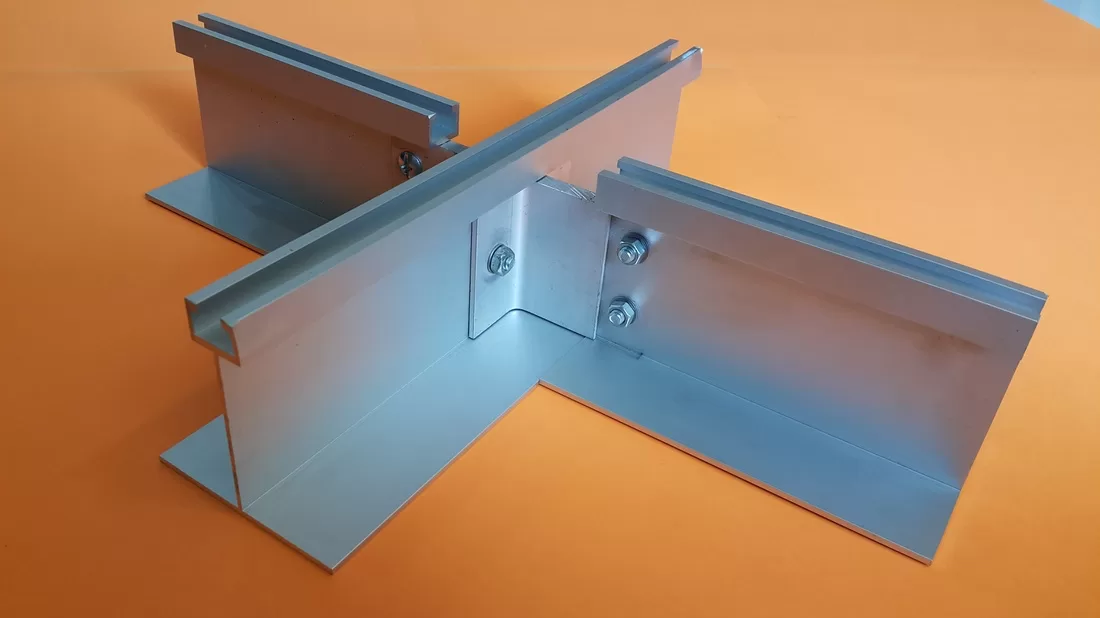

- EEPS offers multiple size cleanroom ceiling solution. We are experience in ceiling systems with superior materials and provides a structural grid system and zinc alloy die-castings.

- The building block of a cleanroom ceiling grid system is the connection / suspension system. We offer extruded aluminium 1”, 2” and 3” cleanroom ceiling systems. The 2” system is the most cost efficient system for cleanroom classes from FSE 100,000 to 10, or any full HEPA coverage application.

T-Grid Ceiling Systems Enhance Cleanroom Security

YECG-1001

YECG-2002

YECG-3003

Doors & Windows

Single Leaf Door _Double Leaf Door

Lockset

Products Specifications:

| Core material | Aluminium honeycomb / Polyurethene (PU) / Polystyrene (PS) / Rockwool |

|---|---|

| Skin | Prepainted steel sheet / stainless steel sheet |

| Hinges | Stainless steel standart type |

| Lockset | Moltise lever lock / cylinder lock |

| Single leaf door size Double lead door size |

Standard 900mm(W) x 2100mm(H) x 40mm(T) Standart 1800mm(W) x 2100mm(H) x 40mm(T) |

| Window | 5mm thickness clear glass or acrylic sheet |

- Specially-designed windows suitable for YE cleanroom wall panel systems with powder coated aluminium extrusions fixed with high quality laminted glass or acrylic sheet to suit your requirements.

- For clean room application, Double glazing window, 45° slope or rounded frame choices are available

Equipments & Accessories

Coving

Vinyl Floor

Epoxy Flooring

Cleanbooth

Air Shower

Raised Floor

Fan Filter units

Pass Box

Clean room contractor Malaysia specializes in the construction and maintenance of controlled environments, ensuring adherence to stringent cleanliness and contamination standards. These contractors employ advanced technologies and materials to create cleanroom facilities that meet the specific requirements of industries such as pharmaceuticals, electronics, and healthcare in the country. Meanwhile, cleanroom Kuala Lumpur are meticulously designed spaces equipped with high-efficiency particulate air (HEPA) filtration systems and controlled airflows to maintain a sterile and controlled environment. These facilities play a crucial role in minimizing the risk of contamination during sensitive manufacturing processes. Together, clean room contractor Malaysia and cleanroom Malaysia contribute significantly to maintaining the highest standards of quality and hygiene in various industries.

Cleanroom Kuala Lumpur specializes in providing high-quality cleanroom solutions for a wide range of industries in the Kuala Lumpur area. Our services encompass the design, construction, and certification of cleanrooms to meet the strictest standards of cleanliness and contamination control. With a team of experienced professionals and cutting-edge technology, we ensure that each cleanroom is tailored to the unique requirements of our clients, whether in the pharmaceutical, semiconductor, biotechnology, or research sectors. From cleanroom design and layout to HVAC systems and filtration, we pay meticulous attention to detail to create environments that maintain precise levels of cleanliness and air quality. Our commitment to excellence and customer satisfaction drives us to deliver reliable, efficient, and cost-effective cleanroom solutions that exceed expectations.

Cleanrooms in Kuala Lumpur provide a sterile and controlled environment, minimizing the risk of contamination during manufacturing processes. This ensures that products, particularly in industries like pharmaceuticals and electronics, meet high-quality standards and are safe for consumers.

Energy efficiency is an important consideration for cleanrooms in Kuala Lumpur to minimize operating costs and environmental impact. Cleanroom companies may employ energy-efficient HVAC systems, lighting solutions, and advanced controls to optimize energy consumption while maintaining cleanliness standards.